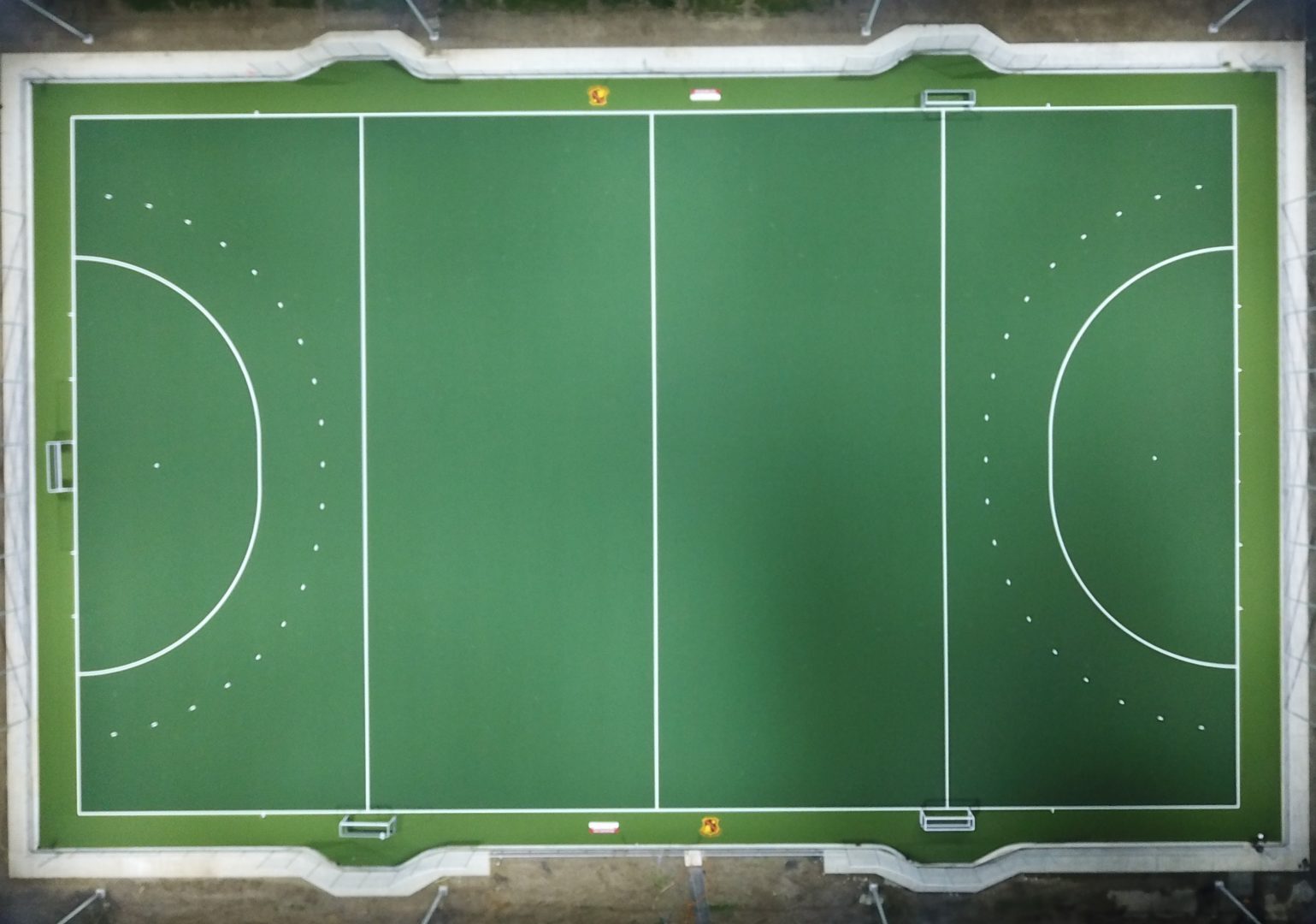

The most recent updates to the FIH Quality Programme for Hockey Turf were made in 2017, bringing in a raft of improvements to the way hockey pitches and products are tested for certification.

Whilst the 2014 FIH Handbook provided an edited and more detailed account of the testing methods used to evaluate hockey products and playing surfaces, the most recent FIH Quality Programme for Hockey Turf incorporated a significant update to the requirements for both products and the field of play.

Here Eric O’Donnell from leading sports surface development experts, Sports Labs, discusses what this means for your new facility.

What do these updates mean for artificial turf end-users and manufacturers?

The upshot of this revision is that products and installations put forward to be certified by the FIH are now more thoroughly examined than they used to be.

For the manufacturer, this means they had to develop new hockey surfaces to meet the requirements, and to develop new surfaces as further criteria are added.

For clubs, schools, or universities investing in artificial turf for hockey, the handbook provides more scope to ensure your facility is certified to the appropriate FIH mark.

What do I need to know about the changes?

All product updates had to be completed by 1st June 2018. So, if you’re planning on investing, it may pay to make sure the surface you have chosen will be future-proofed once installed.

In general, it’s always good practice to check with your installer that the product meets the current standards and that they can honour the warranty.

The number of product classes available for categorising a product has been increased to six. These range from ‘Global Elite’ to ‘Multi-sport’, giving you much more choice depending on the needs of your installation.

The new requirements will also see the materials used to manufacture artificial grass hockey pitches more closely examined for properties such as yarn type, density, and thickness.

Fill materials are also now examined – thus ensuring that the information listed by manufacturers is consistent with what is being installed.

The UV Radiation test, which is conducted on the yarn filaments, within the artificial grass has been increased from 3000 hrs to 5000 hrs.

Additionally, a new test classifying skin friction has been added for ‘Global’ category products – with further tests measuring durability, player-surface interaction, shock pad and toxicology set to be introduced in due course.

Finally, the relatively new format of Hockey 5s courts has been officially introduced into the classification, and can be offered up for certification.

There are a number of other changes that we haven’t gone into here, such as maximum and “preferred” slopes, tightening up of allowable deviations around the mean for ball roll tests, restrictions on pad re-use for some categories and restrictions on colour for some categories.

Please do not hesitate to contact us to discuss how these changes may impact your facility.

There is a lot to take in here, and the impact of any new requirements can sometimes take time to filter through to the market.

However, it’s certainly fair to say that the level of testing of products and facilities has been stepped up – and ultimately, this will help to bring the FIH in line with organisations like FIFA and World Rugby.

Peter Leeves

General Manager for TigerTurf NZ

Mob: +64 (0) 029 201 2479, Tel: +64 (0)09 634 4134,

Email: p.leeves@tigerturf.com or contact us